Explain Different Types of Arc Welding

The various types of arc welding include. Different Types of Arc Welding.

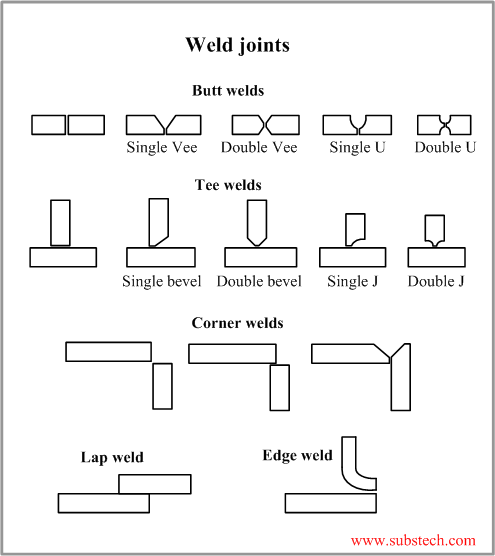

Principles Of Arc Welding Substech

Here electric arc is produced in the gap between the workpieces until the welding temperature is attained.

. The consumption of electrical energy is low as a maximum of 97 of heat energy can be utilized. Shielded Metal Arc Welding SMAW. They melt throughout the process and become part of the join.

Flux-cored arc welding is a semi-automatic or automatic arc welding process. Gas Tungsten Arc Welding. Wire consumption is low.

Arc welding power source. When the power source is turned on the electrode becomes live. Any length can be welded without any interruption.

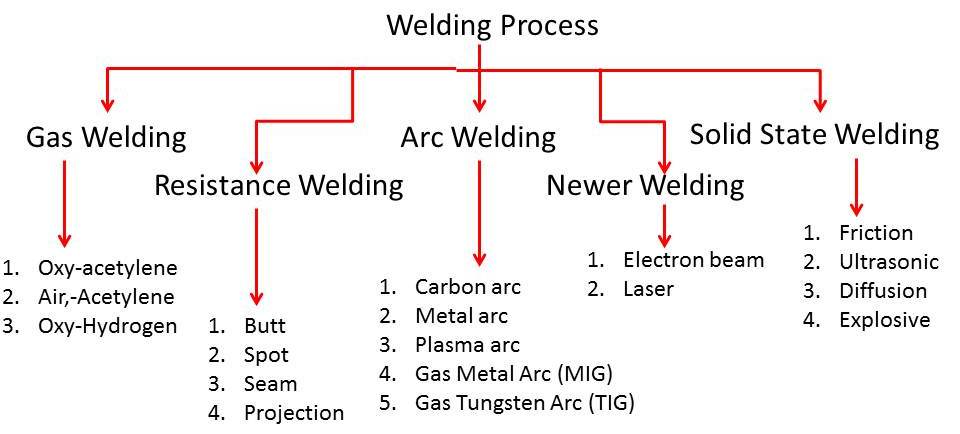

This kind of arc welding is the oldest arc welding process and requires high current low voltage for generating the arc. This process can be categorised into two different types. 4 Different Types of Welding Procedures and When to Use Them 4 Main Types of Welding Processes Shielded Metal Arc Welding SMAW Flux Cored Arc Welding FCAW.

These can be used in both AC and DC welding processes but performs best at DC low current settings. Arc welding is a type of fusion welding and is widely used in. Shielded Metal Arc Welding SMAW Flux Cored Arc Welding FCAW Gas Metal Arc Welding GMAWMIG and lastly Gas Tungsten Arc Gas Welding GTAWTIG.

Shielded Metal Arc Welding SMAW. SMAW Shielded Metal Arc Welding or Stick Welding GMAW Gas Metal Arc Welding or MIG welding GTAW Gas Tungsten Arc Welding or TIG Welding SAW Submerged Arc Welding FCAW Flux Cored ARC Welding PAW Plasma Arc Welding Carbon Arc Welding Stud Welding. By touching the rod to the base metal the current will move through the rod and complete the electrical circuit.

Submerged arc welding is a type of arc welding process that involves forming an arc between the electrode and the workpiece. The gas tungsten arc welding GTAW is also called Tungsten inert gas welding TIGW. Light models only have a thin flux coating and though the shielding gas isnt as strong it does a good job of stopping the oxides.

Arc welding power source comes in two types direct current DC and alternative current AC. There are three types. Ad Shop over 70000 Products 1500 Of The Best Brands.

Consumable and non-consumable electrode methods. A fixed arc is formed between a non-consumable electrode arid a workpiece. These electrodes can be positively charged or negatively charged as the anode or cathode respectively.

The process gives high deposition rates. Ceriated Electrode Orange coded electrode that contains a minimum of 973 tungsten and 18-22 cerium. Gas Metal Arc Welding.

It is popular welding because of its low cost easy and simple operability. Well the advancement of arc welding has brought to a reduction of supply voltage from 200-400 volts to 50-90 volts. There are two primary types of welding electrodes consumables and non-consumables.

Plasma arc welding is a precision technique and is commonly used in aerospace applications where metal thickness is 0015 of an inch. Consumable Electrode Methods Metal Inert Gas Welding MIG and Metal Active Gas Welding MAG Also known as Gas Metal Arc Welding GMAW uses a shielding gas to protect the base metals from contamination. The electrode rod is made of a material that is compatible with the base material being welded and is.

SMAW Shielded Metal Arc Welding. An electric current is used to strike an arc between the base material and a consumable electrode rod or stick. These machines have their own advantages AC power supply is used where electricity supply is available.

Plasma arc welding is very similar in technique to TIG welding but the electrode is recessed and the ionizing gases inside the arc are used to create. There are 4 most common types of arc welding. In some cases an arc can be generated among two carbon electrodes which are named twin carbon arc welding.

From the welding point of view the arcs are of two types viz immobile or stationary or fixed arc and a mobile or moving or travelling arc. It is a type of resistance welding process which can be used for joining together the ends of sheets wires rods or tubes. Ad AI welding to eliminate production gaps produce high quality welds and allow you to scale.

Stick Shielded Metal Arc Welding SMAW These are century-old types of welding processes and improving regularly from time to time. One of the most common types of arc welding is shielded metal arc welding SMAW which is also known as manual metal arc welding MMAW or stick welding. Light medium and heavy welding rods.

High-quality Welds are achieved with no fusion defects no porosity and slag inclusions. FCAW Flux Cored Arc Welding ESW Electro-Slag Welding Arc Stud Welding. Consumable electrodes have a strip of filler metal inside them which gets melted down.

Arc welding is a process where an electrode welding rod is attached to the welding torch which connects to a portable welding machine. 2 rows Types of arc welding. When the rod is pulled back the electrical arc required to melt.

Welding speed is high. Then pressure is applied to produce a continuous weld. The Path Welding Robot collects data and makes adjustments for perfect welds every time.

The principal aim of welding electrodes is to create an electrical arc. One example of such an application would be on an engine blade or an air seal. Although there are still other uncommon types of arc welding the.

Thoriated Electrode Red coded electrode that contains a minimum of 973 tungsten and 18-22 thorium. A blanket of granular fusible material shields the arc on the work. Gas Tungsten Arc Welding.

Types Of Welding Tri State Fabricators

What Are Electric Arc Welding Types Extrudesign

What Is Arc Welding Types And How Does It Work Engineering Choice

Comments

Post a Comment